Sewage, industrial water, and effluent thermal water as an energy source are extremely inexpensive, as unwanted by-products are constantly being generated in industrial plants, large cities, and wastewater treatment plants that can be used in a useful way. Their high temperature heat, with the right technology, for the production of recyclable hot water under the most favorable economic conditions.

Energy conversion technologies

Energy for conversion technologies, which include waste heat recovery systems, have received considerable attention in recent years due to fuel depletion, rising oil prices, climate change and due to global warming

This is an efficient option for utilizing runoff thermal water at 30-500C in high temperature heating systems.

There are many thermal baths in Hungary and a significant amount of thermal water is used for heating. The water used primarily is led to cooling ponds at 30-500C. This causes significant environmental pollution and is also a huge waste of energy. Our waste heat recovery heat pumps are designed for high evaporation and high condensation temperatures. Thus, with our products it is more expedient to utilize the effluent thermal waters with a temperature of 30-500C than to cool them back to a temperature of around 200C and use them with heat pumps designed for low evaporation temperature levels. With this, a large amount of CO2 emission reduction can be achieved. For industrial applications, there are high temperature heating and DHW requirements, which can be met with very high efficiency and significant reductions in energy and CO2 emissions.

In which areas can it be applied?

-

- For the supply of high temperature DHW to hospitals, laundries, restaurants if heat recovery above 300C is available (running water or deep wells)

- For radiator, ventilation heating systems in tall buildings

- To increase the efficiency of district heating

- Wherever waste heat or well water between 300C and 500C is available and high temperature heating is required.

The maximum achievable temperature is 820C.

In industrial systems, it can be designed together for building and process cooling / heating. Our Vaporline GWT systems extract heat directly from well water or waste heat. The maximum permissible temperature of the usable well waters as well as the thermal waters is between 250C and 500C. Temperature control is possible between 500C-820C.

Types of our waste heat recovery heat pumps

- GWT40

- GWT50

- GWT300

- GWT75

- GWT100

- GWT150

- GWT200

- GWT250

- GWT300

Payback time for heat pump systems

Example of an application

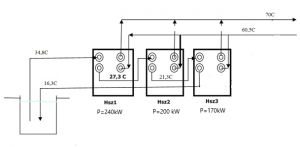

The Vaporline GWT300-H is a special heat pump system developed for the utilization of high-temperature waste heat at a high temperature level. The mass flow requirement of the GWT300 type water-to-water heat pump is 390 l/min. At a water-to-water temperature of 34.8 °C / 70 °C, the heating output is 240 kW. However, to achieve 610 kW, 3 heat pumps are required. The perfect solution for this is to connect three heat pumps in series on the evaporator side, to implement three-stage cooling. By using GWT type heat pumps specially designed for waste heat utilization, we can save up to 5.8 million forints a year with such a system. The calculated payback period is very favorable, up to 2.5 years. For this reason, in the price-value ratio, it is definitely advisable to use heat pumps specially designed for the utilization of waste heat from the heat pump. It can be stated that there are huge opportunities in the high-temperature utilization of high-temperature, treated industrial wastewater, in our heat pumps specially designed and developed for this task, as in addition to the annual utilization and SCOP values, the payback time in the heat pump systems is extremely fast.

Why choose us?

In recent years, our company has developed Vaporline GWT heat pumps for the most efficient recovery of heat energy in effluent from thermal waters. IFrom now on, high temperature heat emitters can be operated with this product family.