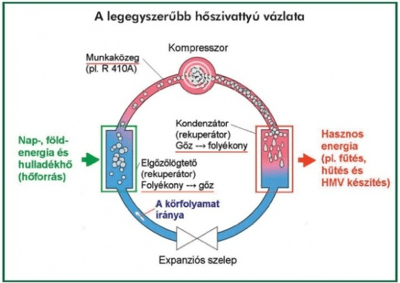

Operation of heat pumps

A heat pump is a heat transfer device that transports heat from a lower temperature level to a higher temperature level. The heat pump uses solar energy stored in natural heat sources – soil, water or air – and together with the driven energy it transfers it to the heating and hot water circuit in the form of useful heat.

In the case of heating, the heat transfer side is the space to be heated. In the case of cooling, the heat energy flows in the opposite direction, the heat is removed from the space and transferred to the air, water and soil.

The cooling-heating cycle

The simplest cooling (heat pump) circuit contains 4 main elements as shown in the picture above. These elements are connected by copper pipes. Refrigerant flows in the copper pipe and in the connected elements (eg R410A). The property of this medium is that it evaporates at very low temperatures as long as it can absorb heat from its surroundings.

Evaporation

If the low-temperature liquid refrigerant in the evaporator comes into contact with the heat of the heat source through the metal wall of the evaporator, which is at a higher temperature than the refrigerant, it evaporates into a gaseous state. However, for the change of state, it absorbs a considerable amount of heat from the heat source (eg soil), but its temperature is low and it is not suitable for operating a heating system.

Compression

The gaseous refrigerant leaving the evaporator enters the compressor, where its temperature also rises as a result of compression, to the extent required by the heating system. Compression requires an electrical energy input. This is the harmful amount of energy. (KWh)

Condensation

The high-temperature, vaporous refrigerant, which contains the amount of energy taken from the ground and introduced to drive the compressor, is in contact with the heating water returning from the heating system through the metal wall of the condenser. The lower temperature heating water releases all its heat content (from the ground as well as the kWh introduced electrically), as a result of which the refrigerant condenses and changes to a liquid state, but its temperature remains high.

Expansion

The high temperature liquid refrigerant leaving the condenser must be cooled to a temperature 4-5 c lower than the heat of the heat source.

For this reason, the refrigerant is passed through a choke (expansion valve). As a result of the choke, a small part of the liquid refrigerant evaporates, which removes heat from the liquid refrigerant to such an extent that its temperature becomes suitable for entering the evaporator

Characteristic of heat pump cycles

The standard cycle shown is typical for household refrigerators, which when used in heat pumps results in a decrease in SCOP value. Unlike refrigerators, heat pumps operate at continuously changing evaporation and condensation temperatures, so that refrigerant charge migration is continuous within the cycle. If this is not compensated, a considerable loss must be expected in the heat pump circuit.

To increase efficiency, actual heat pump cycles may differ from the basic cycle shown for each manufacturer.

Characteristic parameters of the cycle

Heating COP (Coefficient of Performance)

COP = Heat output kW / Electrical input kW

SCOP = kWh of heating energy delivered / kWh of electricity consumed (seasonal indicator)

Cooling EER (Energy Efficiency Ratio)

EER = Cooled power output kW / Electric power consumption kW

SEER = kWh cooling energy consumed / kWh electricity consumed (seasonal indicator)

Vaporline® technology

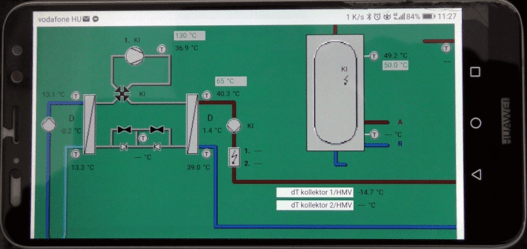

VAPORLINE INTELLIGENT HOME

VAPORLINE heat pumps can be integrated into intelligent home systems through central building management systems and intelligent network interfaces. An Internet modem is standard on all Vaporline heat pumps, allowing you to control your heat pump via PC, tablet or smartphone from home or anywhere in the world

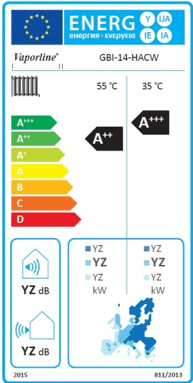

THE VAPORLINE ENERGY LABEL

All VAPORLINE heat pumps comply with the statutory energy label. The energy label provides information on the efficiency of new heat pumps. Vaporline heat pump systems, in line with thoughtful system design, achieve SCOP values that no other heating system can provide.

Pleasant feeling of warmth, quiet operation

VAPORLINE heat pumps not only offer the most pleasant air conditioning possible, they also minimize the sound effect. The compressor and the entire refrigeration circuit rest on a vibration-damped frame that does not come into contact with the outer casing so that vibration is not transmitted. The entire cladding is acoustically insulated to ensure that heat pumps do not disturb the poople ’peace of mind.

HEATING AND COOLING VERSIONS

Every year we suffer from the heat of summer and the number of days above 30 ° C is constantly increasing.

The demand for active cooling in residential buildings is constantly increasing, and EU studies show that the demand for cooling is growing faster than the demand for heating. In cars and many offices, air conditioning is a matter of course, and no one wants to deny this comfort.

Why not realize the same comfort in your own home as you spend most of your life there. Vaporline heat pumps are multifunctional in their basic design. They have built-in heating-active cooling and DHW production functions, so they adapt to the new requirements.

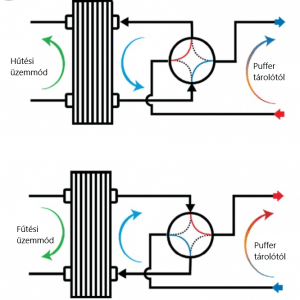

In order to increase the cooling SEER value, it is possible to install a 4-way diverter valve between the heat pump and the buffer tank for multifunctional heat pumps (option). This is necessary so that the evaporator of the cooling mode remains countercurrent when the cooling circuit is reversed. It is advisable to install this in high heat loads buildings for heat pumps. For buildings with low heat loads, the payback takes a long time.

With Vaporline heat pump systems, we can help reduce greenhouse gases in the atmosphere. The heating system of a heat pump consists of a heat source (water, soil, waste heat, or air) and a heat consuming system (eg underfloor heating, wall heating, heaters, etc.).

All system components must be perfectly adapted to the conditions required by the heat pumps to ensure trouble-free operation and high power factors (seasonal power factor).

In order to achieve this, Geowatt Kft., As the manufacturer of Vaporline heat pumps, carries out the complete design of the internal heat dissipation system of the buildings with its design partners. Our system partners will be happy to advise you the professional installation of the system. Geowatt Ltd. offers reliability, an efficient heat pump system, not empty promises.

Stable and high SCOP

- High efficiency and modern compressors

- Application of efficient EVI (Enhanced Vapor Inject) cycle for brine-water heat pumps.

- Optimized operation and control thanks to large evaporators, condensers, electronic expansion valve and quality components

- Stable cycle and efficient operation over the entire operating range to due to equalization of charge migration

Applicability of Vaporline heat pumps

From detached houses, multi-storey residential buildings and entire housing estates to offices, commercial and public buildings, as well as sports facilities and cultural institutions, production facilities and warehouses, etc. - Geowatt Kft. Offers the Vaporline product family for any building.

IN ANY BUILDING

A prerequisite for successful application is that the heating system is designed taking into account the operating range and other operating conditions of the heat pumps as well as the needs of the heating system.

Adaptation to the heating temperature level of buildings

Vaporline® brine-to-water heat pumps can be used at low and high heating temperatures with high SCOP values to meet the heating, active cooling and DHW needs of buildings.

Low temperature heating systems

Vaporline heat pumps can be used with high SCOP values to operate low temperature (35-500C) heating systems.

All possibilities are suitable as heat sources: ground heat, ground water, lake, river, thermal water heat

High temperature radiator systems

The priority area of application of Vaporline GBI heat pumps, heating, active cooling and DHW supply of existing institutional, residential, farm buildings, agricultural facilities is max. At a temperature level of 63 / 570C.

The closed probe heat recovery mode can be used as the heat source.

High temperature / runoff thermal water, waste heat / recovery

The outstanding feature of GWT type Vaporline heat pumps is the utilization of 200C-450C thermal water at high heating temperatures (500C-820C). It can be used in thermal baths, industrial plants, etc. In the case of thermal heating, it can be used to increase efficiency and to make secondary use of thermal heat.

In the case of thermal baths, the thermal energy obtained from the draining thermal water can be used to keep the pools warm, to heat the buildings in winter, and to produce domestic hot water. The amount of heat extracted from the effluent – which is max. It can be utilized at a temperature level of 820C – it reduces the need for thermal energy of the institution, and thus the amount of thermal water used for heating! This will result in a more rational, predictable use of our existing thermal water supply. This is an environmentally friendly technology.

- The environmental benefit of using heat pumps in such a system, in addition to reducing CO2 emissions, is the elimination of heat pollution. In industrial plants, the use of waste heat for building heating, process heating and DHW production is possible. In addition, in industrial technologies, for example, industrial cooling demand can be used simultaneously in a heating, DHW system.

Advantages of using Vaporline heat pumps

Reduce CO2 emissions while heating and cooling at the lowest possible cost!

The fact:

There is currently no more advantageous heating and cooling solution than a reversible geothermal heat pump!

Vaporline is a heating and cooling and DHW system that largely uses renewable energy – geothermal energy – in a price / value ratio that no demonstrable renewable energy system can produce.

-The technique and technology that can be used in the most efficient way, with the highest level of comfort, to replace gas boiler heating systems.

Vaporline heat pumps provide a solution to reduce the costs of heating and cooling and DHW in institutions and residential buildings by 50-60%!

-Vaporline is a system that fits well into the energy strategy, as the / harmful / electrical energy needed to drive heat pumps can be largely replaced by renewable energy with the expansion of the decentralized energy supply!

The most common counter-argument:

-Too expensive, the investment will not pay off in the foreseeable future

With the development of the Vaporline heat pump family (professional, theoretical work, system design), our company Geowatt Kft. Contributes to the creation of efficient, cost-effective, value-for-money heat pump systems.

We think of our future!

The borus vision, it is likely that the price of fossil fuels, and thus the basic living conditions, will be unaffordable for a lot of people in a few years, and in many cases even today!

The solution? The heat pump heating system!

– Which is still the most economically efficient heating system using renewable energy, with the lowest operating costs and the highest comfort.

However, with the increase in energy prices (electricity and gas, oil, etc.), the financial savings available to the heat pump are constantly increasing, as 3⁄4 of the heating energy is taken from the ground for free!

Due to the increase in energy prices, the real payback time is significantly better than the currently forecasted return calculations.

The use of heat pumps is environmentally friendly

CO2 generated during the production of electricity for the operation of heat pumps is constantly decreasing with the advancement of technology, the spread of hydropower, solar and wind energy and connected power plants. For this reason, the use of heat pumps can already reduce the CO2 emissions of a power plant by about 45-60%, if we do not take into account that heat pumps largely use off-peak electricity!

-The use of heat pumps must take into account that it fits well into the energy strategy of the future, which is based on an increasingly on renewable energy sources decentralized energy mix.

The Geowatt Kft through Vaporline’s branded products, does its best to reduce CO2 emissions and maintain ecological balance within the limits of its possibilities.

We hope that you too will feel responsible for the future of our planet, for the next generation, and make a financial sacrifice to reduce CO2 emissions, and install a geothermal heat pump in your home if you have not already done so!

The DHW production

Domestic hot water (DHW) production is the most common task in addition to heating and any active cooling demand. In some cases — hotels, dormitories, condominiums, baths — requires significant power relative to heating power. A common feature of DHW production is that the simultaneities in consumption are high, and therefore the power demand of DHW production is high, which, however, means short-term daily use. The use of a separate heat pump unit for DHW production therefore results in poor unit utilization and thus a high specific (HUF / kWh) investment cost.

DHW supply technique in heat pump systems

There are 4 possible solutions for DHW production for heat pumps:

- Water-to-water heat exchanger applied after the condenser

- With separate DHW heat pump unit.

- Using a primary heat exchanger / Desuperheater /

- Using two capacitors

Water-to-water heat exchanger used after the condenser:

In current heat pump practice, most of the heat pumps on the market use this technical solution to produce domestic hot water for use. In this case, the manufacturer’s basic unit is a simple heat-only heat pump. An DHW module can be optionally fitted to this, which includes the DHW heat exchanger, pump, connection pieces and possibly sensors.

An equivalent solution is to place a DHW bundle heat exchanger in the heating buffer tank, or to heat the DHW tank, or to use the bundle heat exchanger in the tank in a flow-through system for DHW production.

In these DHW production systems, the instantaneous COP and SPF values are the lowest, as the external heat exchange degrades their values by one temperature step. The worst possible solution in terms of both efficiency and investment cost!

A major advantage is that the heat pump device is very simple. However, the reduction in the price of the heat pump is disproportionate to the need for the extra investment and significantly higher operating costs required to achieve adequate DHW comfort.

Use of a separate DHW heat pump unit

Some manufacturers are not developing in the direction of multifunctional heat pumps, but separate DHW heat pumps. In residential buildings, setting up a separate heating heat pump and a separate DHW heat pump is pointless in most cases, as the utilization of the appliances and thus the payback time of the investment is significantly reduced.

The use of low-capacity DHW heat pumps may be justified from an environmental point of view when utilizing the waste heat of buildings (ventilation air, effluent). However, the relatively long payback period of the investment does not allow the use of such devices in most cases.

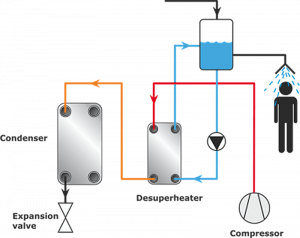

Use of the desuperheater (primary heat exchanger)

The most efficient (high COP) solution used in Vaporline heat pumps!

The heat exchanger (serial connection) installed directly after the compressor and in front of the condenser uses the superheat heat of the refrigeration circuit for DHW production. The superheat range is 12-15% of the total heating output.

The superheat temperature is significantly higher than the condensation temperature, so DHW with a higher temperature can be produced than the heating temperature without deteriorating the COP value.

The other advantage of this solution is that in summer we produce DHW from 12-15% of the heat extracted from the building at no cost, or in other words, it improves the COP (EER) value in active cooling mode!

disadvantages:

- Its capacity is up to 15% of the amount of hot water that can be produced

- Hot water is produced only in heating or cooling mode,

- DHW only cannot be produced this way.

- Additional DHW heating (solar collector, electric insert) is required during the transition period

In residential buildings, with the minimum additional heating, the most efficient solution provides the highest SPF value in the combined mode. The increase in the investment cost of the heat pump with such a “desupeheater” solution is less than two hundred thousand HUF, which already includes the price of the DHW pump. Thus, the price is more favorable than when using an external heat exchanger, when 2 circulation pumps are required in addition to the heat exchanger.

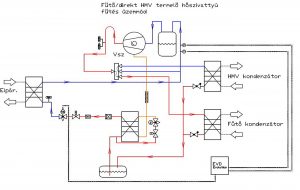

Application of two condenser (direct DHW) heat pumps

An efficient DHW production solution used in Vaporline HDW heat pumps!

In cases where the demand for DHW power reaches 40-50% of the heating capacity or exceeds it, it is advisable this it.

In this cycle, one of the capacitors works in priority switching to DHW, at 100% of its power. The temperature loss is does not occur. Temperature loss does not occur in this case. The most optimal solution for heating and high DHW demand. High temperature (600C) DHW production is possible. With this solution, in many cases it is possible to replace aoccupancy, separate heat pump device. The function change takes place automatically with minimal noise.

In addition to high efficiency, it has the great advantage that it is only suitable for DHW production in summer operation, so its utilization is optimal.

In cases where the demand for DHW power reaches 40-50% of the heating capacity or exceeds it, it is advisable to this it.