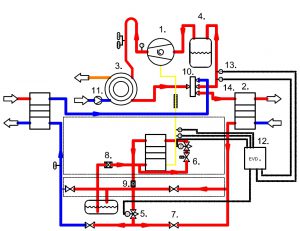

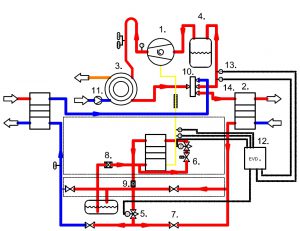

EVI (Enhanced Vapor Inject) multifunction cycle used in Vaporline® GBI heat pumps

- compressor

- plate heat exchangers

- desuperheater

- battery

- EEV valves

- solenoid valve

- non-return valves

- liquid indicator

- filter

- reversing valve

- DHW pump

- EVD driver

- pressure Sensor

- temperature sensor

For COPELAND EVI compressors with steam injection, our company has developed a reversible (heating-active cooling-DHW) cycle. We have implemented this cycle in our heat pumps. The main goal of the development is to achieve the highest possible SCOP value as well as a high heating temperature level. The applied circuit, built-in cooling circuit control and other built-in cooling circuit elements have succeeded in raising the current COP values to a high level, stabilizing the output heating performance at each temperature level, thus achieving higher-than-ever SCOP (Seasonal Coefficient of Performance) heat pumps.

Earth’s heat is an efficient source of energy

This source of energy is available everywhere.

Geothermal heat pumps utilize the solar energy absorbed by the soil as well as the heat flux from the thermonuclear decay of magma. With this renewable energy, they provide an environmentally friendly and efficient heat supply to buildings.

The soil can be considered an ideal heat source, as in winter we remove the amount of heat needed to heat the building from the soil, and in summer we return most of it to the same place with active and passive cooling. In fact, we are just buffering the soil so that we do not increase the heat load on our environment in summer and significantly reduce our electricity consumption.-With climate change, there is an increasing need for active summer cooling, which, when solved with spit climates, requires energy peaks that are already inaccessible in many places, and significantly increases the heat load of our environment.

Thanks to professional engineering design and professional installation, geothermal heat pumps provide the required amount of energy for the building in a reliable way all year round.

Brine-water, heat pump system

The most efficient and safest, best value for money heat recovery solution.

In brine-water heat pump systems, the heat required to heat the building is obtained through probes placed vertically in the ground. Antifreeze mixture circulated by pumps in the probes ensures heat transfer. The generally U-shaped probes are placed in a hole 13-15 cm in diameter, optimally 100 m deep.

The feature of the system is that it utilizes the heat flowing continuously from the inside of the earth, so that the supply is continuous even when the greatest heat demand occurs in winter for heating the buildings.

The heat flux from inside the Earth is the product of the geothermal gradient and soil conductivity. In Hungary, moving away from the surface, the temperature rises by an average of 50-60 ° C per kilometer, which is almost twice the European average (gradient).

The main advantage of the system is that with the help of competent engineering design, the trouble-free operation of the heat pump systems can be ensured without the installation of auxiliary heating systems. Based on long-term thermal impact analyzes, the temperature drop in the soil around the probes is not greater than 0.5-0.60C, scaled for a lifespan of 25 years under our climatic conditions. If the probes are also used for summer cooling, this value will be further reduced.

Disadvantages include:

high drilling and installation costs / in places that are difficult to drill /

drilling is not always possible (eg cavernous areas)

Extraction of geothermal heat with a collector system

This is also called a horizontal collector system)

PE pipes are embedded in the ground, below the frost line, at a depth of about 1.5 m 2 m.

The brine liquid flows through this pipeline and transfers the heat to the heat pump refrigerant through the heat pump evaporator. In this way, the solar energy that has heated the top layer of the soil can be made available for heating purposes.

Because solar energy is primarily used in this heat recovery mode, one of the main requirements for geothermal heat pumps with geothermal collectors is that the area above the collectors be open and unbuilt.

Its installation requires careful, competent engineering planning, because in winter, when the solar supply is low and the heating demand is maximum, – the heat extracted stores the thermal energy stored in the top layer of the earth, thus continuously decreasing the earth’s temperature. In order to prevent overcooling of the soil, the amount of energy to be extracted during the heating season must be calculated accurately, and the collector surface must be determined taking into account the parameters of the ground and the design of the collector system.

One of the disadvantages of soil collector systems is large-scale earthmoving. Indeed, the external heat-generating surface takes up 2.5 to 3.0 times more space than the heated floor area of the building, and this surface cannot be built in and planted with shady trees.

Energy basket

The energy basket also utilizes the solar energy stored in the ground, so its design requires skill. The space required is less than in the case of a soil collector system. The heat output can be around 0.7-2 kW / basket, depending on the basket size and soil conditions.

An important consideration when installing the energy basket is that there must be at least 1 meter of ground above the upper probe loop for safe operation. The energy baskets can be placed in a pre-excavated pit with a machine tool and then connected to a manifold with either a Tichelmann connection or control valves and connected to the heat pump.